Tygon® XL-60

Tubing for food and beverage applications

Superior performance in peristaltic pumps

Designed specifically for use in peristaltic pump applications, Tygon® XL-60 tubing maintains a pump life of over 500 hours. With a durometer hardness of Shore A 60°, it is extremely flexible and exhibits superior flex life, reducing downtime due to pump tubing failure (see "Comparative Peristaltic Pump Tubing Life" on the following page). Tygon® XL-60 tubing can be considered an alternative to silicone and PVC when longer pump tubing life is required.

Excellent physical properties

Tygon® XL-60 tubing is translucent in color and has excellent chemical resistance to a wide range of fluids, including acids and bases. It also exhibits excellent resistance to ozone, oxygen and sunlight aging. Tygon® XL-60 tubing remains flexible at -40°C (-40°F) and is temperature resistant up to +121°C (250°F).

Low extractables

Tubing materials used for food and beverage transfer are not totally inert; hence there may be physical and chemical interactions with the food product, which play a decisive role in the selection of the tubing material. The nature of these interactions includes permeation of gases and vapours across the tubing, migration of tubing components into the food, and sorption of food components. These interactions can give rise to odours and degradation reactions in both the food and the tubing. Tygon® XL-60 tubing was subjected to a migration study with food simulants and the Gas Chromatography Mass Spectrometry (GC-MS) analysis showed that under normal use it does not impart an unwanted taste or odour to the food or beverage being transferred.

Regulatory Compliance

• FDA 21 CFR 177.2600

• NSF 51

• EU Regulation 10/2011*

* For complete compliance information and appropriate use instructions, please refer to the detailed document of compliance.

• NSF 51

• EU Regulation 10/2011*

* For complete compliance information and appropriate use instructions, please refer to the detailed document of compliance.

Features and benefits

- DEHP free

- Long flex life in peristaltic pumps

- Temperature resistant up to +121°C (250°F)

- Low extractables

- Alternative to PVC

- Clear and flexible

- Custom colors available

Typical applications

- Food and beverage transfer

- Peristaltic Pumps

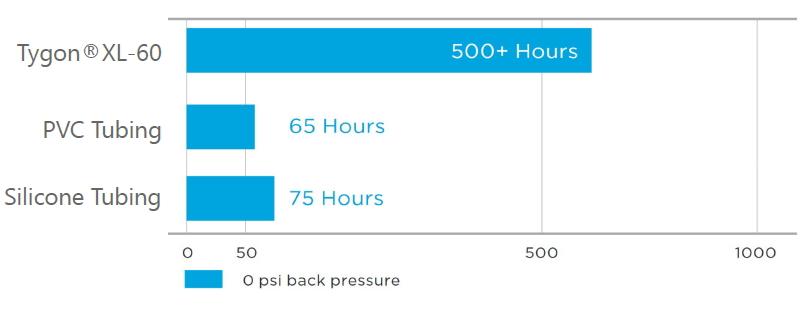

Comparative peristaltic pump tubing life relative permeability coefficient

The table below depicts hours until failure of 6,35 mm (1/4") ID x 9,53 mm (3/8") OD tubing. In each case, a 3-roller pump head operating at 600 rpm under room temperature 23°C (73°F) conditions were utilized. Tubing failure is measured in hours of use prior to rupture.  The performance of tubing in peristaltic pumping applications is affected by the conditions of use and equipment utilized, along with size and wall thickness of the tubing tested. The data above is presented for information only and should not be utilized for specification purposes.

The performance of tubing in peristaltic pumping applications is affected by the conditions of use and equipment utilized, along with size and wall thickness of the tubing tested. The data above is presented for information only and should not be utilized for specification purposes.

Relative permeability coefficient

TYGON® Tube XL-60 - Diameters and wall thickness

| Art.No. | Ø Inner | Ø Outer | Wall | Inch rounded | Crossref. |

|---|---|---|---|---|---|

| TY1,59XL4,76 | 1,59 mm (1/16") | 4,76 mm (3/16") | 1,59 mm (1/16") | 1,6 x 4,8 x 1,6 mm | AN800003 |

| TY3,18XL6,35 | 3,18 mm (1/8") | 6,35 mm (1/4") | 1,59 mm (1/16") | 3,2 x 6,4 x 1,6 mm | AN800007 |

| TY4,76XL7,94 | 4,76 mm (3/16") | 7,94 mm (5/16") | 1,59 mm (1/16") | 4,8 x 8,0 x 1,6 mm | AN800012 |

| TY6,35XL9,53 | 6,35 mm (1/4") | 9,53 mm (3/8") | 1,59 mm (1/16") | 6,4 x 9,6 x 1,6 mm | AN800017 |

| TY7,94XL11,11 | 7,94 mm (5/16") | 11,11 mm (7/16") | 1,59 mm (1/16") | 8,0 x 11,2 x 1,6 mm | AN800022 |

| TY9,53XL12,7 | 9,53 mm (3/8") | 12,7 mm (1/2") | 1,59 mm (1/16") | 9,6 x 12,7 x 1,6 mm | AN800027 |

| TY12,7XL19,05 | 12,7 mm (1/2") | 19,05 mm (3/4") | 3,18 mm (1/8") | 12,7 x 19,1 x 3,2 mm | AN800038 |

| TY15,88XL22,23 | 15,88 mm (5/8") | 22,23 mm (7/8") | 3,18 mm (1/8") | 15,9 x 22,3 x 3,2 mm | AN800046 |

| TY19,05XK25,4 | 19,05 mm (3/4") | 25,4 mm (1") | 3,18 mm (1/8") | 19,0 x 25,4 x 3,2 mm | AN800053 |

Typical Physical Properties of Tygon®XL-60 Tubing

| Property | ASTM Method | Value of Rating |

|---|---|---|

| Durometer Hardness | D2240 | 60° Shore A, 15s |

| Color | - | clear |

| Tensile Strength | D412 | 11.2 MPa (1.630 psi) |

| Ultimate Elongation | D412 | 770,00% |

| Tear Resistance | D1004 | 33.3 kN/m (190 lb-f/in) |

| Specific Gravity | D792 | 0.90 |

| Compression set Constant Deflection, 22 hrs. @ 70°C | D395 | Method B 55,00% |

| Tensile Modulus @300% Elongation | D412 | 3,83 MPa (555 psi) |

| Tensile Set @75% Elongation | D412 | 100 |

| Dielectric Strength | D149 | 21,6 kV/mm (550 v/mil) |

| Maximum Recommended Operating Temperature | - | 121 °C (250°F) |

| Brittleness by Impact Temperature | D746 | -66°C (-87°F) |

| Water Absorption, 24 hrs. @ 23°C | D570 | 0,07% |

TYGON®XL-60 TUBING IS NOT INTENDED FOR USE AS AN IMPLANT MATERIAL.